Saving Energy, Improving Work Efficiency, High Temperature Resistance, High Power Supply, F-Class Yellow Self adhesive Teflon Coil, Multifrequency Transformer for Photovoltaic Equipment

Product name: F-grade yellow Teflon self-adhesive coil

The heat resistance level of the product has passed UL testing and reached Class F155 ° C heat resistance level. The product is widely used in fields such as high-frequency power transformers and magnetic rings,the product uses various imported high-temperature resistant PET. PA and other high-tech materials to improve its temperature resistance and high pressure resistance,We can produce multi-layer insulation wires with colors such as two or three layers according to requirements. Users can also choose red, yellow, blue, green, etc,complies with ROHS and REACH halogen-free requirements

Coil material:Self adhesive yellow Teflon insulated wire MIW-F 4UEW

Winding method:

- Self adhesive yellow Teflon insulated wire MIW-F 4UEW for wire cakes

- The outer winding of the wire cake is 16TS (8+8), without cutting in the middle, with three layers of single cake

- The coil should be free from accumulation, the inner circle of the wire cake should be free from scratches or broken skin, and the wire cake should not be loose

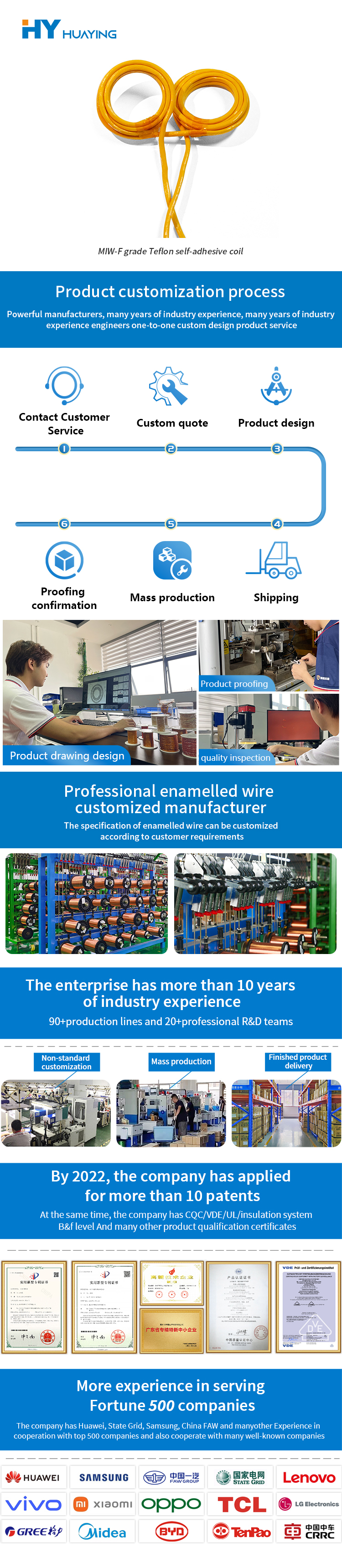

Huaying Electronics' self-adhesive coils can be divided into PET self-adhesive coils, Teflon self-adhesive coils, enameled wire self-adhesive coils, silk wrapped wire self-adhesive coils, high-temperature film wrapped wire self-adhesive coils, etc; According to different temperature resistance levels, it can be divided into 130 degree self-adhesive coils, 155 degree self-adhesive coils, 180 degree self-adhesive coils, etc; According to the molding conditions, it can be divided into thermal fusion coils and solvent fusion coils; According to the formed shape, it can be divided into circular coils, elliptical coils, rectangular coils, and other customized shapes; According to the quantity, it can be divided into single cakes and multiple cakes in series

Coils of the same wire type perfectly inherit the physical and electrical characteristics of this type of wire, and customized winding provides favorable conditions for production miniaturization and automation

All products undergo a complete and rigorous set of physical and electrical tests before leaving the factory to ensure that their quality meets the customer's application requirements

1-300x300.jpg)