Enamelled copper stranded wire H-class charging pile high temperature stranded square coil automotive electronics high temperature and pressure resistance

High temperature stranded square coil

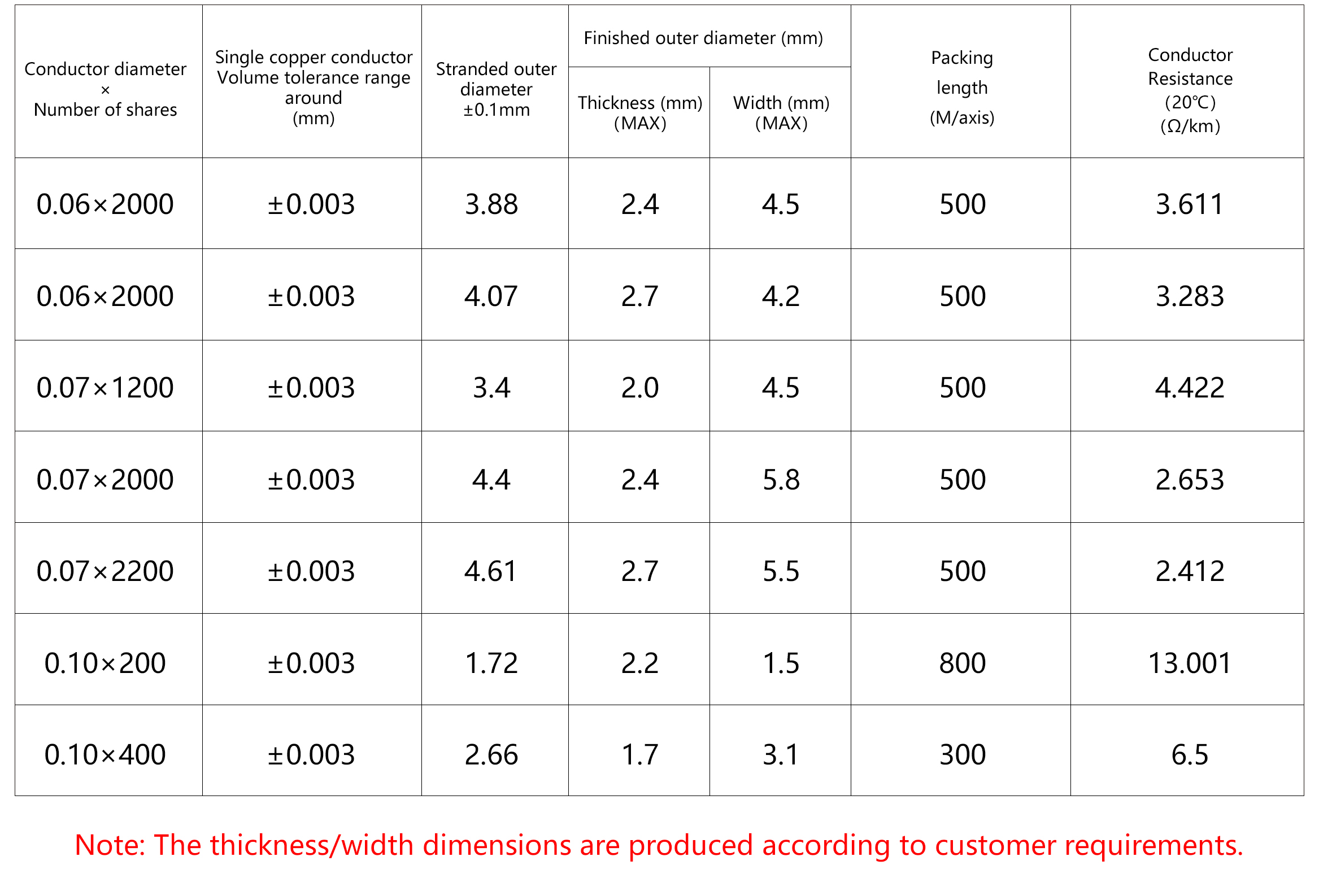

product name:High temperature stranded square coil

scope of application:This product is used to wind high-frequency electronic transformers, and the coil needs to be small in size and high in power.

Thin thickness or high temperature resistance, safety special transformers, such as charging piles, optical storage, automotive electronics and special

Transformers for medical equipment and other products

Temperature and pressure resistance level:

- Product name mark: MIW-H

- Product name: high temperature stranded square coil

- Temperature resistance grade: H=180℃

- Conductor wire diameter example: enamelled copper stranded wire

Insulation material: high temperature tape (brown)

safety certification; material certification:

UL: E470559 (single product safety certification)

UL: E472956 (insulation system certification)

VDE:40047994

CQC: 18001197439 (certificate number)

Substance detection: SGS ROHS2.0 MSDS

Appearance standard:

- The surface should not be scratched, damaged, knotted, peaked, or wrinkled, and the internal and external marks should be consistent.

- Inspection method: visual inspection

Withstand voltage:

Straight line withstand voltage test:

Wrap the linear sample with a length of 305mm tightly in the middle area of 152mm with thin metal, and then

Apply AC 3500v voltage between the metal film and the conductor for 60 seconds.

Requirement: No breakdown during voltage application

Solderability:

- Standard: tinning is bright and full without residue

- Inspection instruments: temperature inspection equipment to check the temperature of the tin furnace

- Inspection method:

3.1 Take a sample of 12cm stripping tape on the finished shaft

3.2 The temperature of tin furnace (420℃±5℃) takes about 4-6 seconds

Pinhole:

1、Standard: 0 pinholes

2、Inspection instrument: pinhole testing machine

Inspection method: Take a 1.5m or 6m long sample wire from the finished coated wire, and immerse the sample more than 5 meters in 3% phenolphthalein and alcohol and 2% saline in a non-bending and non-extending state. Apply 12V voltage to the formed test solution for 1 minute to check the number of pinholes produced

-300x300.jpg)