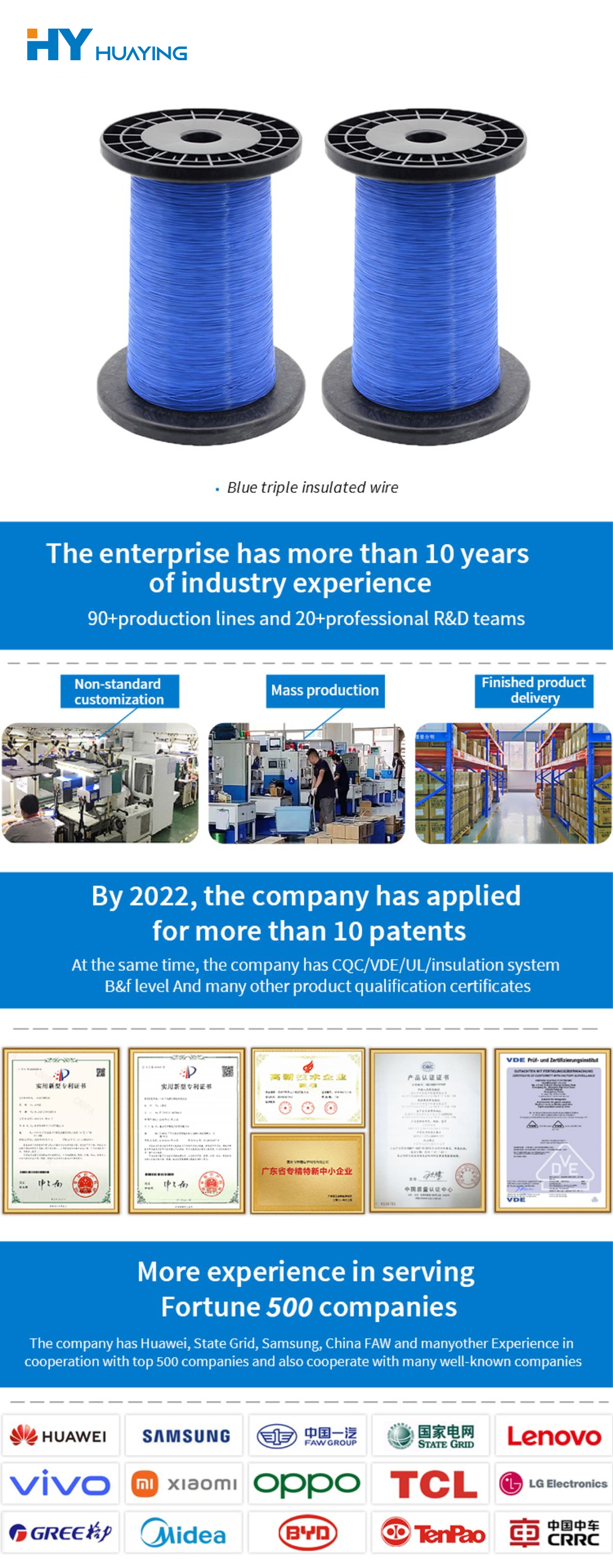

Blue three-layer insulated wire factory customized delivery

Elongation detection

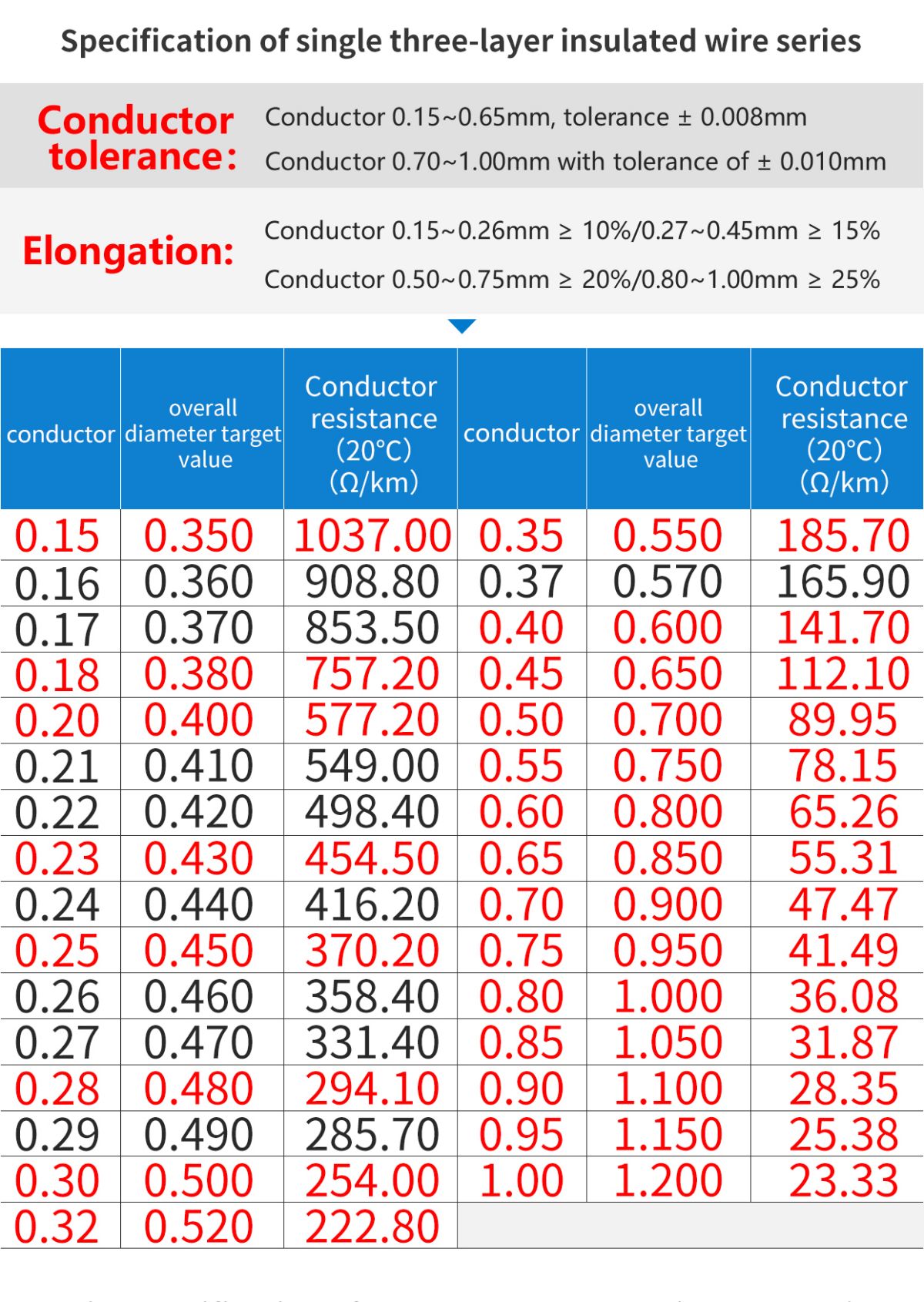

Take a sample with a length of about 400mm from the finished product line, make a standard line distance of 250mm in the central part, and pull it off with a tensile machine at a speed below 300mm/min. After connecting the cut parts, measure the length between the standard lines, according to The elongation is calculated by the following formula: (For example: if the sample is broken outside the standard line, the test is considered invalid,) (see Table 7 for its inspection standards)

Elongation (%) = (length between the standard lines of the connecting and cut-off part (mm) - distance from the original standard line (mm)) ÷ distance from the original standard line (mm)

Thermal Shock Test

Take a sample of at least 305mm and tightly wind it on a smooth round rod as shown in Table 4 for 10 laps at a winding speed of 1 to 3 laps per second, and apply a tension of 118Mp/mm2 on the wire to make it tightly Stick it on the round bar. During the winding process, it is necessary to avoid the elongation, overlap and damage of the sample. Take the sample from the round bar and put it in the oven at the temperature shown in Table 5 for 30 minutes. The error of the oven temperature is 5C, take the sample out of the oven, let it cool down to room temperature naturally, and then use a magnifying glass with a magnification specified in Table 6 to observe whether there is cracking on the surface of the sample

Product information

1.Product name: Blue triple insulated wire

2.Model: Three-layer single insulated wire/three-layer multi-strand insulated wire

3.Color:Blue

4.Insulation material: PET+PET+PA

5.product specification:0.15~1.00mm(Specifications can be customized)

6.Conductor material:Single-core bare copper, enameled wire, tinned wire (three-layer single insulated wire) Multi-core enameled wire or tinned wire (three-layer multi-strand insulated wire)

7.Dielectric strength:6KV/5mA/1min

8.Insulation Thickness:0.09-0.1mm(three layers of insulation, each layer thickness0.03-0.035mm) (single) 0.1mm (thickness of each layer of three-layer insulation: 0.03-0.035mm) (multiple strands)

9.Advantages: Three-layer insulated wire does not require interlayer insulation tape or barrier, which has the advantages of reducing the size of the press, improving efficiency, and reducing costs.

10.Heat-resistant temperature and voltage:130℃(Class B)~155℃(Class F)

11.Application field:Three-layer insulated wire is widely used in electronics, communications, military industry, aerospace and other fields, such as: high-frequency electronic transformer switch electronic transformer, various transformers in the IT industry, electrical switchg base material